This site provides schematics of various radio projects that you can experiment yourself.

Wednesday, 9 March 2011

CRYSTAL TESTER

Figure shows the circuit of a simple crystal tester. It switches on a light emitting diode (LED) if the crystal is working.

The crystal under test is placed in an oscillator circuit. If it is working, an RF voltage will be present at the collector. This is rectified (converted to DC) and made to drive a transistor switch. Applying current to the base causes current to be drawn through the collector, thus lighting the LED.

If an indication of frequency is required, simply use a general coverage receiver to locate the crystal oscillator's output. Note however that when testing overtone crystals (mostly those above 20 MHz) the output will be on the crystal's fundamental frequency, and not the frequency marked on the crystal's case. Fundamental frequencies are approximately one-third, one-fifth or one-seventh the overtone frequency, depending on the cut of the crystal.

The circuit may be built on a small piece of matrix board and housed in a plastic box. Alternatively, a case made from scrap printed circuit board material may be used. Either a selection of crystal sockets or two leads with crocodile clips will make it easier to test many crystals quickly. The RF choke is ten turns of very thin insulated wire (such as from receiver IF transformers) passed through a cylindrical ferrite bead. Its value does not seem to be particularly critical, and a commercially-available choke could probably be substituted.

The circuit can be tested by connecting a crystal known to work, and checking for any indcation on the LED. A shortwave transistor radio tuned near the crystal's fundamental frequency can be used to verify the oscillator stage's operation. Note however that this circuit may be unreliable for crystals under 3 MHz, and some experimentation with oscillator component values may be required.

The crystal checker also tests ceramic resonators. Other applications include use as a marker generator for homebrew HF receivers (use a 3.58 MHz crystal) and as a test oscillator for aligning equipment.

Figure Two:

Ten Steps to QRP Success

1. Use efficient antennas

A half wave dipole or better is preferred.

2. Know your capabilities - do not expect DX every time

It would be nice to work Europe with one watt to a mobile whip on forty metres, but do not expect such contacts to come easily (if at all). Instead, you should cast your sights a little lower and enjoy the closer-in contacts that are more achievable.

3. Have frequency-agile equipment

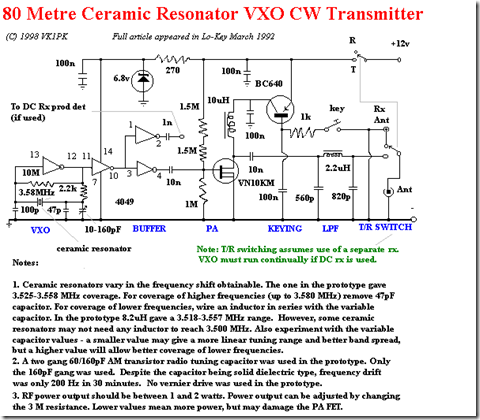

Many articles describe simple crystal-controlled QRP transmitters that can be put together in an evening. These are fun to build but frustrating to operate; 99 percent of such rigs sit on shelves, unused, gathering dust. Instead, use a VFO or 3.58 MHz variable ceramic resonator on eighty metres, or a VXO with at least a 10-15 kHz tuning range on the higher bands.

4. Use 'tail-ending' to advantage

When your signal is weaker than average (such as when operating QRP), 'tail-ending' is the most effective way of obtaining contacts. Simply tune across the band, noting the contacts that are ending. When all stations sign clear, call one of the stations. They will most likely reply to your call, even if only to give a signal report.

5. Have a quality signal

A transmitter that clicks and chirps is harder to copy at the other end than a signal from a clean and stable rig. This is particularly the case when the receiving station is using narrow CW filters.

6. On CW, know the relationship between your transmit and receive frequencies

It is possible for a station to miss your call if you are transmitting on the wrong frequency. Set direct conversion QRP rigs so that they transmit about 800 Hz below their receive frequency. Conversely, if calling CQ, tune around your normal receive frequency (with the RIT control) just in case a station is calling you on the wrong frequency.

7. Have an efficient transmit/receive switching system

A homebrew station that requires the operator to flick two or three switches to switch from receive to transmit is inefficient and may result in missed contacts (particularly during contests). Use just one T/R switch or experiment with the many break in and timing circuits available.

8. Use the best receiver you can afford

Most of the complexity in a QRP station is in the receiver. While simple receivers are fine for casual SWLing, active operating requires a somewhat better class of receiver. Aim for good frequency stability, adequate bandspread, reasonable selectivity, good strong-signal handling and an absence of microphonics. A well-built direct-conversion receiver should satisfy on all five counts for all but the most hostile band conditions.

9. Enter contests to boost your operating skills

Many people think that high power is necessary to participate in contests. This is untrue, particularly for the local VK contests. Contest rules are given in Amateur Radio magazine and on the WIA website.

10. Don't be afraid to call CQ

On bands such as ten metres, the band can be wide open, but no one would know as every body is listening. Call CQ, particularly when you have grounds for supposing the band is open, for example reception of beacons or 27 MHz CB activity. Automatic CQ callers using tape recorders, computers or digital voice recorders are particularly handy here.

One Valve CW transmitter

This transmitter was first constructed in 1987 and provided the author with his first 'real' rig, capable of distances of more than about 100 metres. It performed better than expected, with 250km contacts being commonplace and 2500km being occasionally possible.

It consists of a 6GV8 valve, common in the many valve TVs that were rusting in rubbish tips at the time. Unlike some slightly simpler designs, it is a two stage circuit, the triode section being used for the oscillator and the pentode as the power amplifer. With a high tension of about 200 volts power output of about 3 watts could be obtained on 3.5 MHz.

It will work with the cheap 3.58 MHz crystals, but you won't get many contacts up there – better to invest in a lower frequency crystal – eg 3.530 MHz or so. A VXO is not provided – these do not usually provide much shift with 3.5 MHz crystals. However if you wish to add one, wire an inductor (approx 6.8uH) in series with the crystal and add a variable capacitor from point 'A' to earth.

A circuit for a power supply is not included. The one used for this project is based on a transformer from an old valve radio. Use a bridge rectifier and electrolytic capacitor (rated at 350v or so) for smoothing. However as the current drawn is low, even a single 1000v diode will work as the rectifier in this circuit.

Like nearly all valve circuits, this transmitter uses lethal voltages. It should be fully enclosed so that no high voltage points can be touched by the operator. A metal chassis, such as a cake tin is suitable.

To test, insert a crystal, wire a small light bulb (eg dial light) across the antenna terminals and press the key. Adjusting the Tune and Load controls should cause the light to glow quite brightly. Plate current should be around 30-50mA. For the transmit/receiving switching, either have the receiver connected to a separate antenna or use a switch or relay to switch the antenna over.

N4UY 40M RF Power amplifier

This 40 meter amplifier posted Is handy for boosting the power of rigs running a few hundred milliwatts, and can put out 2 or 3 watts.

The RF enters through a 0.1 uF cap and a small ferrite bead to the PA transistors. A 2 uH inductor provides a DC return for the bases. 12 volt is applied to the collectors through an 8 uH choke. A 47 pF electrolytic cap and 0.1 pF cap bypass unwanted signals from the V+ source to ground.

L Match Tuner for End-Fed wire antenna

In this tuner. a variable inductor made bv mutual coupling between two coils of near equal inductance is used as the L match inductor. The object is to have a variable inductor with no taps or rollers. These coupled coils, LI and L2 are connected in series (see Figure) to get total inductance.

A reverse switch connects the two coils either for additive or subtractive M to accomplish a wide range of total L. With LI = L2 = 10 uH and K = 0.8 the range is about 4 to 36 uH. One coil is wound on the plastic case of

a 12 ga empry shotgun shell and the other on a 20 ga empty shotgun shell . The winding is #23 magnet wire so that the outside diameter of the 20 ga coil slides nicely into the 12 ga shell to allow variable coupling by sliding the smaller coil in and out of the larger coil.

1. Use a low base 20 ga empty shotgun shell and drill out the primer end to clear a 114 inch screw.

2. Take a 1/4-20 nylon hex nut and glue it over the hole just drilled. This gives the shell a threaded nut that will run on a lead screw to move this coil in and out of the 12 ga shell.

3. In preparation for winding the coil cut off and discard about 318 inch of the crimped end of the 20 ga plastic so that a well formed coil form remains.

4. Locate and drill a 1132-inch dia hole in the plastic about 114 inch from the end just prepared. This is for the start of the $23 magnet wire winding.

5. Locate and drill another 1132" dia. hole in the plastic about 7116 inch from the fust hole toward the base. This allows 15 turns between the holes from start to finish, Drill a 1W-inch hole close to the base that will serve to bring both ends of the winding out for connections clear of the sliding fit. .

6. Wind 15 turns of #23 magnet wire between the two 1132 dia holes. Start with one end into a 1132 dia hole, into the shell and out the 118-inch hole. When 15 turns are on, put the end into the nearby 1132- inch hole, down the center of the shell and out the 118-inch hole pulling the wire tightly to maintain tight turns.

7. Take a 12 ga shell, cut the crimped end off to make a uniform coil form and wind on 13 turns of #23 magnet wire. No holes are used for the start and finish of the winding so tape must be used hold the winding and dress the leads. Clear fingernail polish may be useful as well.

8. A 1/4-20 x 2 inch nylon machine screw along with an extension of 114 inch wooden doweling is used to make the lead crew shown in the diagram in Figure

Noice source

A broadband noise source is useful for testing purposes. This circuit gave a reasonably flat output up to 30 MHz when checked with a general coverage receiver. The output impedance is about 50 ohms. It's basically a zener diode used as a noise source with a broadband RF amplifier. I think the higher power zeners give more noise, which is why I used a 1W device. The zener voltage isn't critical, of course; use whatever you have around 6V. The 4:l transformer is 8 bifilar turns on a SiemensEPCOS B64290P37X33 ferrite toroid. An FT37-43 could be used.

FM Superregenerative Receiver

The oscillator coil is made from five turns of 0.8 mm (ideally, silver plated) copper wire on a diameter of 8 mm. Short connections are essential, especially to the tuning capacitor: we soldered a trimmer directly to the ground plane. The second coil in the circuit consists of 20 turns of 0.2 mm enamelled copper wire wound on a 10 kÙ resistor. The rest of the circuit is constructed as shown in Figure.

The antenna should not be too long, as otherwise the circuit may cause interference: the superregenerative circuit is also a transmitter! Nevertheless the circuit is very sensitive and operates perfectly satisfactorily using a 10 cm length of wire for an antenna. The headphones should ideally have an impedance of at least 400 Ù. The circuit will work with 32 Ù stereo headphones, but the output will not be as loud. It is important to use a transistor designed for radio frequency use (such as the BF494) as it is difficult to get the circuit to work using an ordinary audio frequency device such as the BC548B.